Shipping Box Engineering: Hexabox Wine Shippers

At Gorilla Shipper, we set out on a mission to create a high-quality solution to ship wine without worry. To do this, we designed a shipping solution that was sustainable and secure enough to ship wine bottles and glass products from anywhere. Through a series of testing, analysis, and dedication from our engineering team, Hexabox was born.

Our unique, patented design took years of research and engineering to get the complete product we know and use today. Our team went to great lengths to develop our trademark Hexabox wine shipping boxes, and we couldn’t be more proud of the results.

We want to walk you through every step we went through during the engineering process and provide you with an in-depth understanding of how we developed the Hexabox wine shipper.

Let’s get into it.

The Hexabox design process

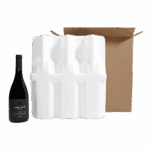

Our Hexabox is a 100% recyclable, patented 6-panel design was engineered to keep your products safe and secure, no matter the circumstances. We’ll be the first to tell you it wasn’t easy to conceptualize.

Our engineering team was dedicated to the process and took every necessary step to create the product our clients use today. On top of that, we weren’t willing to cut any corners or reduce the function requirements of the final product.

Here are the steps we needed to take in the early design process:

- Solve a problem for a clients

- Conduct competitor research

- Create a design that meets patent restrictions and our goals

- Conceptualize a prototype

- Conduct rigorous testing and protection analysis

- Go through verification and validation

- Pass the ISTA 6-FEDEX-A testing process

This is just to name a few of the steps we needed to take to get our final product. This doesn’t include the hours of work put in by our engineering team, the prototypes that lead us to our final version, or the various levels of testing we needed to pass to ensure we were developing a design that met our standards.

The early stages of the Hexabox

During the early stages of engineering the Hexabox design, our team went through a series of trials and errors to develop what we have today. We set out to improve the marketability of shipping glass and wine bottles and create a unique design that can accommodate different types of products.

We wanted to be “the” shipping solution for glass and wine bottles of all kinds, and that’s what we did. Before getting started, we outlined our goals and considered our customers’ needs. We used our motivation to push us towards success and always stayed true to our overall goals.

To put things into perspective, here are a few of our goals for the Hexabox wine shipper:

- Improve the marketability of shipping glass

- Develop a universal design that could accommodate different wine bottle sizes

- Stick to a sustainable and eco-friendly solution, no matter what

- Ensure our product was cost-effective for the customer

- Take our competitors’ products to the next level

- Pass the ISTA 6-FEDEX-A testing process

These goals helped us turn our vision into a reality. We weren’t willing to let the Hexabox be anything less than what we envisioned.

The problem we set out to solve

We’ll be honest: during the early stages of development, we didn’t see a product on the market that met our standards. We believe that our customers deserve more than average. They needed a solution they could trust, no matter the situation. We wanted to create flexibility for our customers and provide them with reassurance every step of the way.

To do this, we knew we needed to design a product that was unlike anything else on the market at the time. We considered the advantages, disadvantages, and challenges we may face along the way. Our constraints may have made it harder to get where we needed to be quicker, but they also showed us just how limited the market is and why.

We needed to keep our manufacturing cost low for the Hexabox wine shipper to keep the price reasonable for our customers. Not only that but being environmentally friendly was at the forefront of our goals. Which caused limitations during the early stages. However, we knew the final product would have the capability to outshine any other solution on the market. All we needed to do was solve a problem, stick to our goals, and consider all options.

How we planned to do it

Once we knew what we wanted from our wine shipping boxes, we set out to turn it into a reality. Keeping wine or other glass bottles safe no matter where it was shipped was our focus. We wanted our concept to protect the wine bottles from breaking, no matter what happened. That means it needed to prevent breakage from reasonable heights and withstand unpredictable vibrations during the shipping process. Anything can happen when a package is en route. That’s why we knew we needed to provide a solution that could handle anything.

Once we understood our functional requirements, we started planning how to get where we needed to be. No matter what happened during testing and analysis of our prototypes, we stuck true to our goal of keeping our manufacturing costs low, providing a high-quality design for a reasonable price to our consumers.

Not only that, there were restrictions we needed to abide by to ensure we got the patent. To do this: our concept needed to be a single piece of corrugated cardboard and also form two adjacent triangles. It wasn’t easy to develop an advanced wine shipping box out of one single piece of material. Our team worked hours, trying to configure and formulate a design that could meet the needs of Gorilla Shipper, our customers, and the patent requirements.

We knew our design needed to be marketable and improve the experience for the user and the consumer.

That’s where the real fun began.

The Hexabox design went through many prototypes, tests, and analyses to get it where it is today. We developed practical tests that generate data to help us revise and adjust our prototypes. Through a series of testing we determined the areas of improvement for our early designs. Which helped us compare and highlight the strengths of our wine shipping boxes when we later compared them to our competitors.

Flexibility for our customers

When we first designed the Hexabox, we wanted to make sure our unique wine shipper solution was able to securely fit two wine bottles of varying sizes so that wineries and wine sellers didn’t need to buy multiple sizes to accommodate their product offering.

We also wanted to make it easy for the consumer to remove the bottles from the wine shipper when they arrived. By considering this as an extra step, we would ensure the glass products were less likely to break upon delivery.

Our team wanted to do more than create bottle shipping boxes we could be proud of. We wanted them to be easy to use and low-cost for our customers.

During the development process, we decided to put together an assembly time test with random individuals to truly put our prototypes to the test. Our research showed that the average person took less time to fold the Gorilla wine shipper than our competitors. When given instructions, the average assembly time decreased for participants.

This was important because it meant that our Hexabox had the power to increase efficiency and streamline productivity for our customers. We keep things simple yet high-quality.

Rigorous Product Testing

A protection analysis is a process used to determine if our product could withstand high-consequence scenarios. During our protection analysis of our later prototypes, we compared our design with our competitors in a drop test and a strength to cost ratio test. What we found was that our wine shipper provides the most protection for wine bottles among the most popular cardboard shipping solutions on the market. Not only that, but our final prototype provides the most protection per unit price among the same competitors.

For us, this was groundbreaking. It showed our engineering team that we were capable of not only reaching our goals but exceeding them. The results made it clear that Hexabox had the power to dramatically change the way we ship glass while still being an easy-to-use solution for our customers.

Taking the extra time to go through this long-winded protection analysis and testing process means that we will be able to out-market our competitors in the future.

Taking our original Hexabox wine shipper design to the next level

Once our team went through all of the needed testing and analysis, we understood where we needed to improve our original concept and customize our product to meet the needs of our customers.

We decided to add finger holds to our original prototype. This added modification didn’t affect the structural integrity of the shipper, which means our testing data below would remain unaffected. However, we thought this was a needed addition that could help improve the process for our customers.

After these minor adjustments to our potential prototype, we started the lengthy verification and validation process.

During this time, we needed to prove the durability and simplicity of the Gorilla wine shipper through testing and creating the CAD drawing of the altered shipper with the handle.

We were almost to the finish line.

However, our team didn’t stop there. We knew that if we ever wanted to reach our goals with the Hexabox, we needed to get it approved and tested by the ISTA 6-FEDEX-A.

What is the ISTA 6-FEDEX-A testing process?

During the ISTA 6-FEDEX-A testing process, a single product sample is dropped differently ten times. The product testers make sure to hit every corner or edge of the packaging to ensure there aren’t any weak spots in the product. If any of the products inside of the boxes break, it’s an automatic fail. It’s a lengthy and difficult test to pass.

However, we knew if we were going to go to great lengths to design and conceptualize a wine shipper design like the Hexabox, we needed it to pass this test, too.

The Hexabox wine shipper you use today

We’re proud of how far our design has come and its unique ability to keep your wine safe and secure for the entire duration of its trip. Whether it’s a bottle of wine or a bottle of olive oil, you can rest assured that there are years of work and engineering that went into developing the Hexabox you use today.

Now, we help wineries, breweries, and everything in between confidently ship their bottles all over the world. We’re America’s #1 choice for wine and spirits shippers, and we couldn’t be more proud of the progress we’ve made throughout the experience.

We knew creating the Hexabox wasn’t going to be easy. We had a list of requirements, and we never had to cut any corners to get to the end product.

Whether you’re new to Gorilla Shipper or you’ve been a customer of ours for a while, you can rest assured knowing that all of our products are engineered and developed to be a high-quality and eco-friendly design. We proudly make all of our Hexabox wine shippers in the U.S.A and always make sure they are the safest and most reliable option you can choose.

Our very own patented Hexabox has come a long way, and we wouldn’t change one thing about the rigorous process it had to go through to reach our goals. Next time you use our Hexabox as a wine shipper or a beer bottle shipper, remember that it was engineered with care and that we appreciate your support.