How to Choose the Right Void Fill for Your Packaging Needs

Are you hunting for the ideal void-fill packaging to safeguard your items during shipping? Look no further. Finding the perfect solution can be confusing, but we are here to simplify the process for you.

By familiarizing yourself with the various available materials, you can make a knowledgeable decision to ensure your products arrive safely and undamaged. In this article, we cover the steps to take before making any purchases and discuss various void-filler options for packaging to help you choose the best one for your needs.

Analyze Product Dimensions and Weight

Selecting void-fill packaging for a product can be a tricky process. Therefore, you must weigh each item and measure its physical dimensions to find a durable material that prevents shifting. The key to successful shipping is to use fillers that provide the right amount of stability and cushioning while eliminating any excess space.

During transit, shipments get tossed around frequently, so you need to know the specifics to protect your product from occasional bumps that can cause damage or breakage. Analyzing your products beforehand will help you choose a solution that protects products and provides a secure fit.

Evaluate the Types of Product You Plan to Ship

Evaluating the type of products you plan to ship is critical when comparing void-fill packaging. When you thoroughly understand your product, you can choose a material that suits your individual product needs and save time and money.

For example, when dealing with fragile items like electronics and appliances, protective void fillers for packaging, such as air pillows or bubble wrap, are necessary to ensure safe delivery and keep each item from sustaining damage.

On the other hand, a simple solution like craft or corrugated paper can work perfectly for clothing or cans. Peanuts or styrofoam sheets may be more suitable to protect glass bottles due to their added cushioning capabilities.

Assess the Environmental Impact of the Void Fill

As the effects of climate change continue to become more severe, we must consider the environmental impact of our actions whenever we make decisions. Therefore, you should choose more sustainable options like paper or biodegradable materials to meet your shipping needs.

Of course, this will not be an option for every product. But if possible, try to use recyclable or compostable void-fill packaging, as these will keep harmful plastics out of the ecosystem once materials reach the end of their life cycle. Materials such as corrugated bubble wrap, green wrap, and tissue paper are easy to recycle and can help you attain your sustainability goals.

However, foam peanuts and plastic bubble wrap are non-recyclable and create unnecessary waste. If you care about the environment and these options suit your needs, keep this in mind when selecting fillers for packaging your products. In the long run, your decision will help reduce single-use plastic waste, lighten the burden of landfills, and preserve the planet for future generations.

Determine the Cost of the Void Fill

Cost is of the utmost importance when choosing void-fill packaging solutions, as different materials can affect your bottom line in several ways. To make an educated decision, you need to consider several factors, including materials, weight, quality, purchase volume, and current pricing, to stay on budget.

For instance, when determining if materials like bubble wrap and air pillows are the best solution, remember they contain petroleum-based plastics or resins. That means the cost is usually linked to oil prices and is subject to fluctuations. So, even though air pillows and bubble wraps are lighter than paper, their pricing is affected by the petroleum industry. When oil prices are high, they may not be the most cost-effective void fill for packaging your products.

For even lower shipping costs, it is wise to purchase void-fill materials in large quantities to qualify for volume discounts. Doing so will allow you to decrease the number of orders and take advantage of the market when pricing is more affordable. In addition, always remember that quality matters because it directly affects replacement costs. Lower-priced fillers for packaging may sound like a great idea until you have to replace products due to inferior-quality packaging.

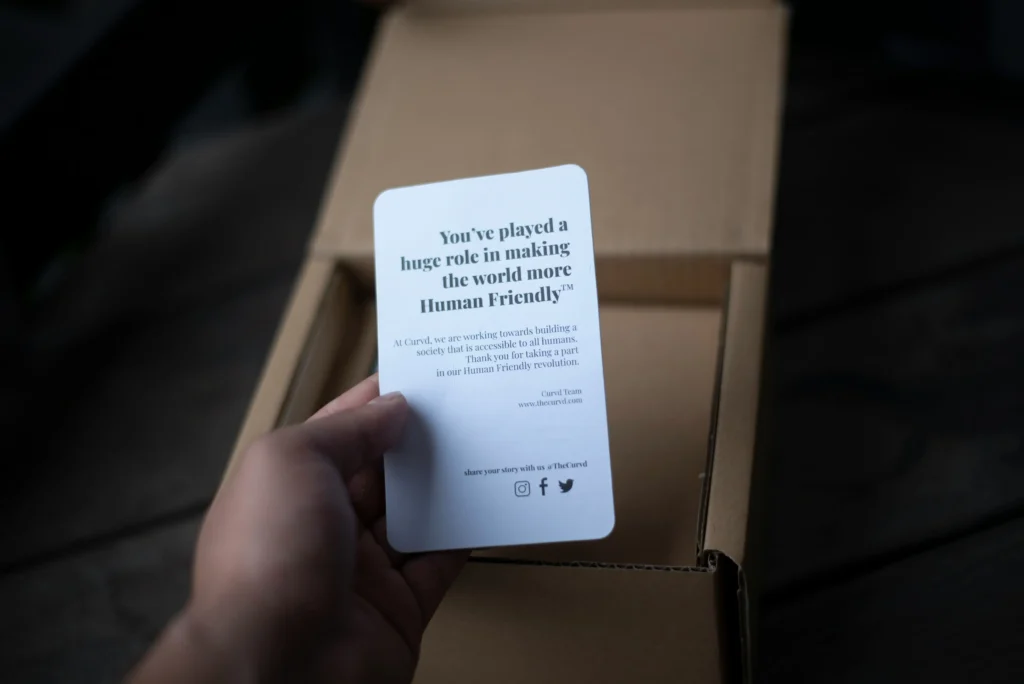

Examine How the Packaging Presents Itself to Customers

With the way modern shopping works, be it online or in person, first impressions count. So, ensuring your goods arrive in packaging visually consistent with your branding is imperative. Presentation is everything, and the overall aesthetics, including the void-fill packaging, will immediately impact customer perception.

After all, customers want more than just what they find inside the box. They also need to feel a holistic experience with your products. Consumers expect congruency between brand messaging and your actions. Therefore, your best strategy is to choose a filler for your packaging that does not detract from the overall look and feel of your brand.

With attractive and sustainable filler materials inside, you can effectively reinforce brand identity and confirm your messaging to the customer. Without question, this is the best way to distinguish your products from the competition and build a customer base full of repeat buyers. In reality, packaging designs can be just as recognizable as any logo or product itself, so be sure you examine every detail to ensure each shipment looks its very best.

Consider Shipping Environments and Availability

When shipping items, it is best to use void-fill packaging that can withstand changing temperatures, dust, moisture, and other unpredictable conditions. Depending on your product, an item exposed to extreme heat or cold temperatures while in transit or at a warehouse is more likely to become compromised or damaged. So, monitor potential weather conditions and inquire about the shipping environments before making a purchase.

Also, ask the supplier about availability before placing your order. Keep the conversation laid back and friendly, and check if they can guarantee on-time deliveries to ensure you can obtain a steady supply. The answers will directly affect future purchases. If the timeline does not meet your expectations, take your business elsewhere.

Deliver Your Products Safely With Gorilla Shipper

Choosing the right void fill for your packaging needs can be a time-consuming process. But it is necessary to ensure your products arrive safely at their destination. This helps you avoid replacing damaged goods and keeps your customers happy. With a bit of research, you can find the right filler for your packaging that protects your products and bottom line.

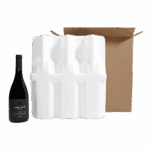

If you ship bottles, jars, or cans, you can protect your goods with Gorilla Shipper’s packaging solutions. Our shipper kits come with an outer box and corrugated cardboard, molded pulp, or foam inserts that secure your products without the need for filler materials. All our packaging solutions are certified by the International Safe Transit Association (ISTA) and recommended by FedEx and UPS for shipping fragile items.

Browse our packaging products to find the best protective solution for your needs.