7 Trends in the Packaging Industry

Trends in the packaging industry are ever-changing as new technologies, consumer behaviors, and economic realities take hold.

Whether you work in the shipping industry or rely on packaging to drive your business, it’s important to stay up to date on the latest trends. This can prepare you for any challenges that come along while also ensuring you’re one step ahead of your customers’ needs.

The following are just a few of the biggest trends in the packaging industry right now.

1. Digital Printing

Digital printing technologies have opened up a world of potential for customized packaging. Since 2018, digital presses have exceeded traditional typesetting presses for package printing. Unlike traditional offset printing, digital printing can get the job done without the operator ever having to switch plates.

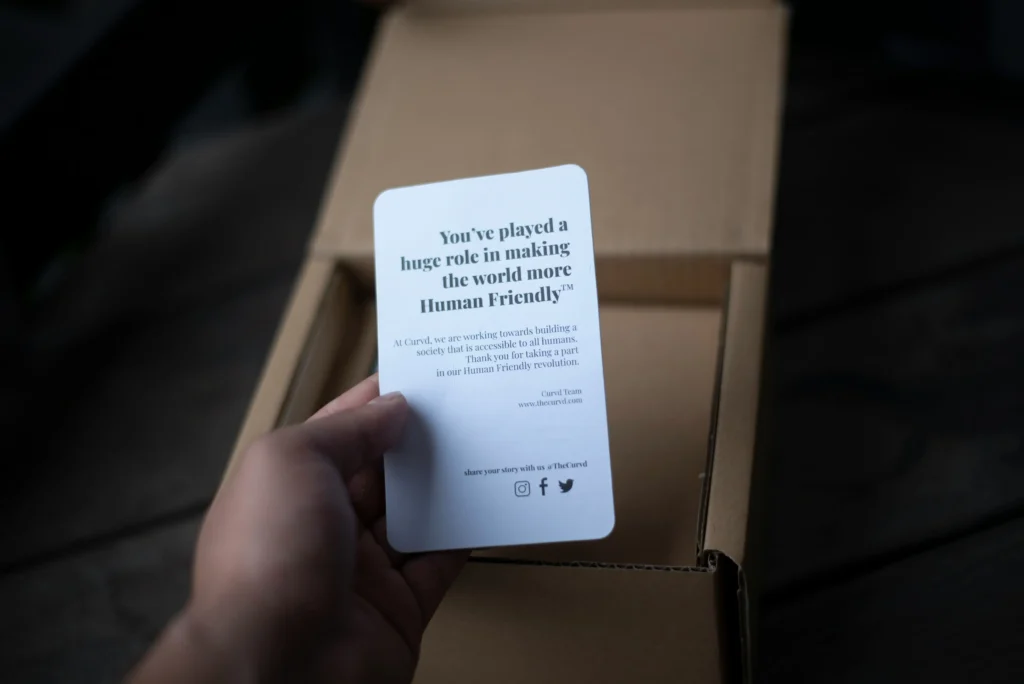

Because digital methods allow all colors to be printed simultaneously, printing on demand has become one of the hottest new packaging trends. This makes it easier, faster, and more cost-effective for many businesses to personalize packaging on behalf of clients.

When you add it all up, custom packaging is no longer seen as a luxury but is becoming imperative for businesses seeking to make a positive presentation.

2. Sustainable Packaging

Consumers are demanding sustainable products more than ever. And a growing number of packaging companies are getting on board. This is easily one of the most influential trends in the packaging industry.

According to a Forbes report, consumers across all generations are willing to spend a bit more on sustainable products, including nearly 90% of Gen Xers. Just two years ago, only 34% of Gen Xers said they’d be willing to pay an extra 10% for sustainable products.

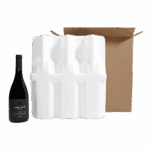

As a result, sustainable packaging is becoming more common in the marketplace. For instance, Gorilla Shipper’s Hexabox packaging and pulp inserts are designed to be environmentally friendly, with 100% recyclable and biodegradable materials.

When seeking the best types of packaging materials for shipping, don’t neglect the value of sustainability.

3. Reduced Reliance on Bioplastics

This goes hand in hand with the previous trend, but the movement away from bioplastics is a trend unto itself.

In recent years, bioplastics have seen a surge in popularity in response to the growing number of single-use plastic bans. Because many bioplastics are biodegradable, they’ve been marketed as an eco-friendlier alternative to the petroleum-based plastics that have long dominated the market.

However, the tide is turning as we learn more about the true environmental footprint of bioplastics. While there’s still a lot we don’t know about bioplastics, it turns out that they may be much more difficult to compost and recycle than originally assumed. And even though they’re not petroleum-based, their creation still requires considerable natural resources.

So in a world where sustainability is becoming one of the biggest new packaging trends, bioplastics are slowly falling out of favor.

4. Ecommerce-Friendliness

The COVID-19 pandemic has ushered in a golden age of online shopping, and it doesn’t show any signs of slowing down. What started as a necessity (coping with lockdowns) has expanded into a broader cultural realization of the benefits of having everyday goods delivered.

This cultural shift has necessitated closer partnerships between ecommerce brands and the packaging providers they rely on. For instance, packaging providers are becoming increasingly concerned with creating custom packaging solutions that adhere to their client’s brand guidelines and sizing needs.

This trend is closely linked to the digital printing trend, as the improvement of digital print technologies is making it easier for packaging providers to customize packaging for each brand they serve.

5. Domestic Manufacturing

The COVID-19 pandemic has also led to another new trend in the packaging industry: demand for packaging made in the USA. As many international supply chains remain in limbo, more businesses are specifically seeking out packaging materials manufactured domestically.

That’s not to say that there aren’t supply chain issues within the U.S. There are still driver shortages, warehouse staff shortages, shipping delays, and production challenges. But these problems are heightened when dealing with foreign providers. In addition, working with international providers can create further issues like language and time zone barriers.

Finally, domestic packaging providers are more likely to be up on the current regulations. For instance, all packaging bound for shipment must meet certain requirements established by FedEx, UPS, USPS, and the International Safe Transit Association (ISTA). That’s why, at Gorilla Shipper, we maintain domestic operations throughout the USA and ensure that our packaging materials are approved by all relevant regulatory bodies.

By working with domestic packaging providers, businesses are able to save both time and money and prevent unnecessary delays in their own supply chains.

6. Automation

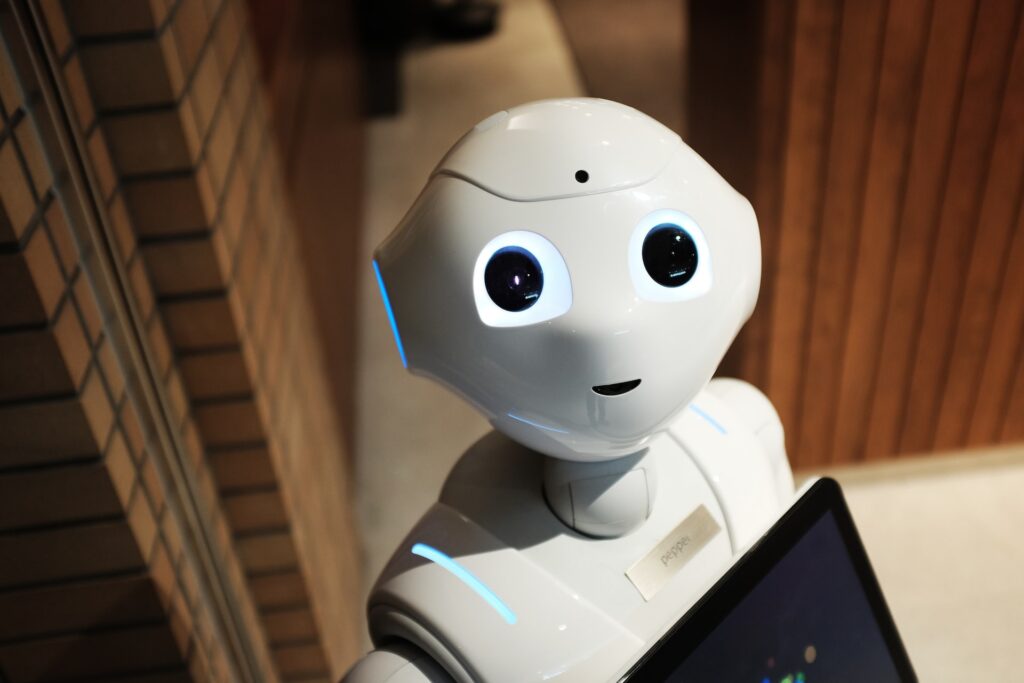

Automation is leading the charge in many industries, and packaging is no exception.

Precision automation means greater output without sacrificing quality control, which is becoming essential in an age of increasing output demand and ongoing hiring challenges. State-of-the-art robotic arms and grippers are able to handle the most delicate products and keep the cargo moving without the risk of human error.

Some businesses are even employing state-of-the-art AI systems that use photographs and machine learning to assess the quality of packages. Although this is becoming one of the biggest trends in the packaging industry, it’s still relatively new and in its infancy. We can expect this trend to grow in the coming years.

7. Ease of Assembly

This relates back to the increase in customization. More custom packaging means more of a learning curve for the product manufacturers who rely on that packaging. That’s why it’s so important to design packaging that anyone can assemble quickly without a lot of hassle.

For instance, at Gorilla Shipper, we provide six-sided boxes that are easy to assemble with a few quick folds. Our customers are provided instructions for quick, simple assembly. We also offer video tutorials.

Take our Standard Pulp Shippers, for instance. Each order contains everything needed for quick assembly and safe shipping. The same goes for our Standard Hexabox Shippers. We even have kits that come pre-assembled.

Shop Innovative Packaging from Gorilla Shippers

Whether you’re dealing with plastic shipping containers or corrugated shipper boxes, it’s important to keep up with new trends in the packaging industry. Packaging materials are often overlooked and forgotten, but they’re absolutely critical. Without them, your goods can never hope to reach their destination in one piece.

If you need innovative packaging solutions for bottles, jars, or cans, look no further than Gorilla Shipper. We offer packaging products in different sizes and materials to satisfy every business need. If you have any questions about our packaging solutions, contact us to get more information.